Since 2001, New Euroart has been working in the field of construction and erection of industrial plants, overseeing projects from their design and fabrication to installation and start up.

New Euroart activities have been continuously focused on customer satisfaction and improving quality standards. The future guidelines will include the most advanced technologies, environmental sensitivity and safeguarding, and the adoption of measures aimed at reducing or eliminating risk or hazardous conditions.

By working with international customers, leaders in the sectors of Oil & Gas,

Power Generation and Off-Shore, the company has acquired high technological and methodological standards.

With the desire to maintain the high levels and to further improve them, New Euroart highly focused on quality, safety and the environment. On the one hand, the existing technical and management skills guarantee reliability in project execution and flexibility, but on the other hand, the main factors for the development and continuity of the business are based on advanced technologies and attention to the market’s needs.

The company strategy aims to take up the challenge of a rapidly changing market due to technological innovation.

New Euroart is a market oriented company which aims for customer satisfaction.

New Euroart s.r.l. has adopted its own Code of Ethics and a Model of Organization, Management and Control, in compliance with the principles and guidelines provided by Legislative Decree 231/2001 (Rules governing the administrative liability of legal persons, companies, firms and associations, including associations without legal personality).

» Integrated Policy New Euroart » Model ex D.Lgs. 231 of 2001 » Social Responsibility SA 8000:2014 » Gender Equality Policy

Bridgecranes

Double girder system up to 50 tons

Pick and Carry electric cranes – 33 tons

Pick and carry diesel cranes – 45 tons

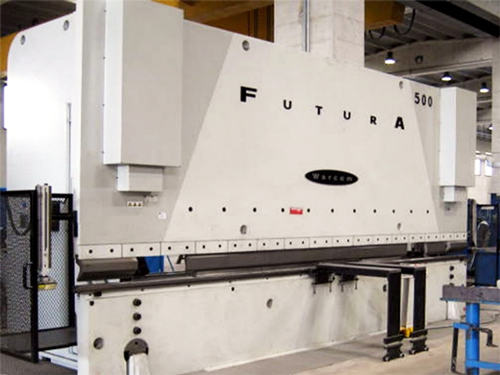

Mechanical cutting & bending 500 tons

Thanks to its own equipment and skilled workers,

New Euroart performs metal sheet bending operations from 1 to 10 mm thick (8 mm max on 6000 mm length)

Press brakes 500 tons

Lenght: mm 6000

Max Capacity: Tons 500

Work Lenght: mm 6200

Distance between columns: mm 5050

Speed: mm/s 0÷6.5

Power Engine: Kw 37,5

Plate bending machine

MG Plate bending machine, Model MH225D-S

Lenght mm 4220

Width mm 1920

Work height mm 1100

Total height mm 1850

Work Lenght mm 2050

Upper steamroller: diameter mm 290

Lower steamroller: diameter mm 300

Power Engine kw 11

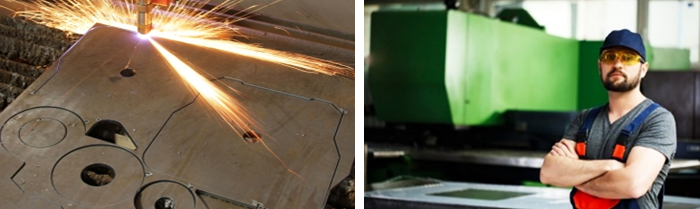

Plasma cutting machine

Automatic machine SOITAAB OVER 3000 x 12000

Cutting size: mm 3000 x 12000; Plasma Generator: Hypertherm HPR 400 XD MGC

Thickness: mm 0,6 – 50; Positional accuracy: mm ± 0,05

Motorisation: Brushless; Driving: Digital

Band Saw SHARK 310 CNC-HS

Numerical control band saw with automatic development

Vice width: 315 mm; Cutting capacity: 310 mm

Development: automatic and programmable

Cutting of metal sheets and section bars

New Euroart also performs cutting of metallic raw materials such as metal sheets and section bars made of stainless steel and carbon steel.

Thanks to the plasma cutting machine, it is possible to cut thick plates up to 130 mm.

Calendaring of metal sheets

Tickness up to 130 mm

Submerged Arc Welding

Miller Dimension 1250 (Tandem – DC/AC)

Floor type boring Machine SAN ROCCO FUTURA 13 CNC

X Axis Travel: 6000 mm; Y Axis Travel: 2500 mm; Z Axis Travel: 797 mm

Spindle Diameter: 130 mm; Rotary and traversing table: 2000 x 2200 mm

Cross movement: 1500 mm

Bench Lathe DORMAC mod. DORIA 460

Chuck: Ø 800 mm; Distance between centers: 2000 mm; Spindle bore: Ø 80

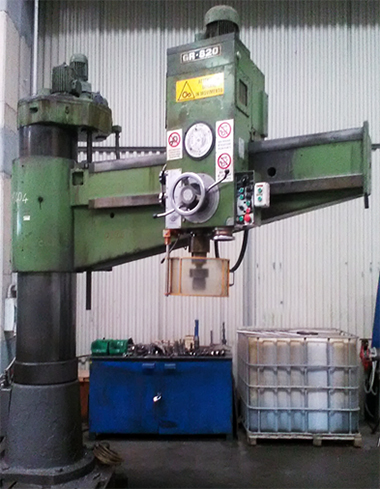

Radial Drilling Machine INFRATIREA GR 820M

Ø max. drilling capacity steel: 80 mm

Ø max. drilling capacity casting: 100 mm

Spindle taper: MORSE 6

Arm movement: 1600 mm

Max Distance spindle nose to base: 1800 mm

Ø Column: 500 mm

Boring, Turning, Drilling

Boring, Turning and Drilling are regularly provided for the realization of own production

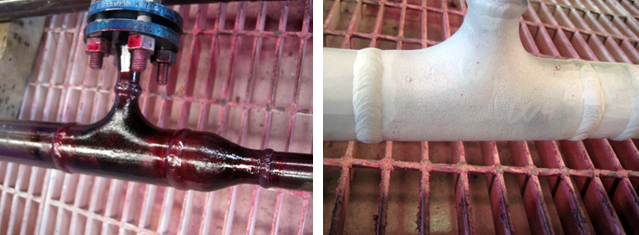

Non destructive tests

New Euroart performs non destructive tests (LP, VT, MT, UT) at its own premises

Only RX are provided by external support